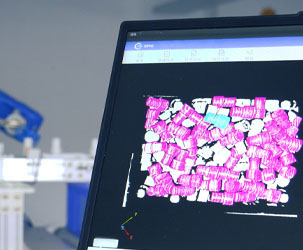

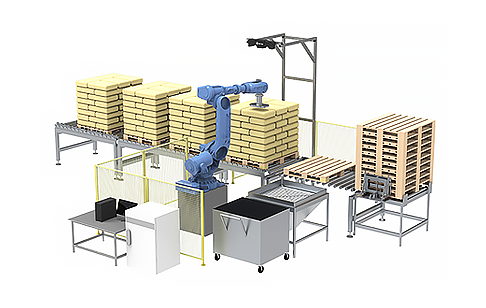

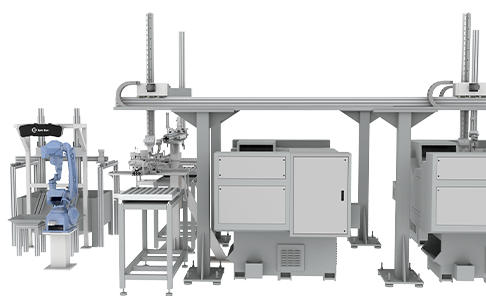

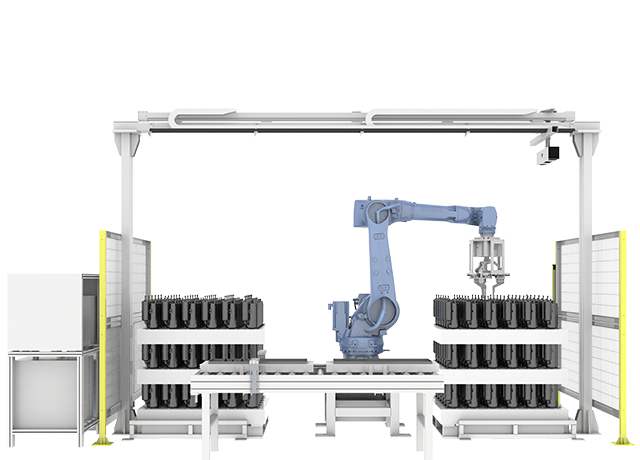

3D vision-guided technology ensures the robot can accurately detect the position of workpieces, achieving millimeter-level precision in assembly. This significantly enhances product quality and consistency.

Minimize manual intervention, reducing labor costs while avoiding human errors, ensuring the stability and reliability of the assembly process.

The system is unaffected by the placement of workpieces, allowing the robot to handle randomly placed objects, increasing the adaptability and flexibility of production lines.

By boosting production efficiency and reducing error rates, this solution can significantly lower production costs in the long term, delivering higher returns on investment for customers.