Partnering with Integrators

Driving innovative applications across industries

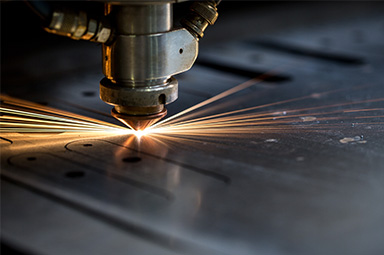

In the field of metal processing, the application of 3D vision technology enables the accurate recognition and grasp of complex workpieces, especially in the face of high-reflective and high-temperature working environments, while maintaining a high recognition rate and stability. It optimizes the processing process through intelligent algorithms, improves product quality, reduces production costs, and accelerates the intelligent transformation of the industry.

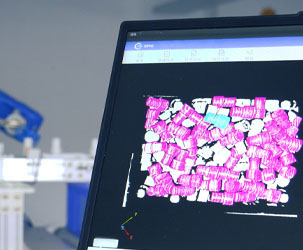

Pick and Place of Electronic Control Units

For the disordered and semi-disordered loading and unloading challenges of the automotive industry, intelligent identification and accurate positioning are provided to achieve automated and efficient operations, significantly improving the flexibility and throughput of the production line, while reducing labor costs and ensuring production continuity and product quality.

Consult Now

Consult Now

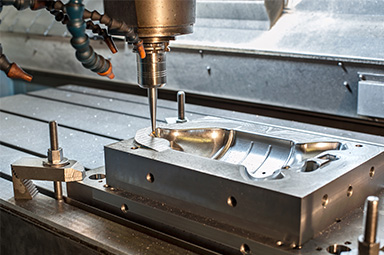

Machine Tending of Half-shafts

The 3D vision system improves the intelligent recognition ability of the robot, ensuring that the robot can flexibly grasp the workpiece placed at random, and accurately complete the assembly of the specified position. This technology not only optimizes the production process, improves efficiency and accuracy, but also brings the dual value of cost savings and quality assurance to the customer.

Consult Now

Consult Now

Pick and Place of Engine Flywheels

With an advanced vision system, the robot can efficiently and accurately select the workpiece from the neatly arranged or disorganized material frame and place it precisely on the machine or conveyor belt, significantly increasing the automation efficiency.

Consult Now

Consult Now

Partnering with over 300 integration partners

We’ve driven the intelligent transformation of nearly 100 production lines across diverse industries.