ABB crane systems help Rotterdam grow ABB起重机系统助力鹿特丹港发展 2006-01-16 - Rotterdam, the world’s second largest port by cargo volume, is expanding capacity by 25 percent to meet the global boom in container traffic. ABB is supplying advanced integrated automation and electrical systems for the 76 terminal cranes. 2006-01-16—世界上第二大货物吞吐量港鹿特丹港正以25%的速度增长以满足全球集装箱运输的飞速增长。ABB为其76台港口起重机提供先进集成自动化和电气系统

The port of Rotterdam is booming. Container traffic in 2004 grew by 16 percent to 8.3 million twenty-foot equivalent units (TEU), each unit corresponding to a 20-foot long shipping container. 鹿特丹港正在飞速发展,2004年的集装箱吞吐量上升了16%,达到830万个标准箱单位 (TEU),每个单位对应一个20英尺的船运集装箱。 With growth in traffic expected to continue, Europe Terminal Operators (ECT) and A.P. Moller - Maersk are building a new container complex that will expand capacity at Rotterdam by an additional two million TEU containers a year. 因人们预计集装箱的运输量将持续增长,欧洲港口运营公司(ECT)和A.P.穆勒—马士基公司正在联合新建一条集装箱码头,这样鹿特丹港每年将可以吞吐多2百万个TEU的集装箱。

The port of Rotterdam is booming. Container traffic in 2004 grew by 16 percent to 8.3 million twenty-foot equivalent units (TEU), each unit corresponding to a 20-foot long shipping container. 鹿特丹港正在飞速发展,2004年的集装箱吞吐量上升了16%,达到830万个标准箱单位 (TEU),每个单位对应一个20英尺的船运集装箱。 With growth in traffic expected to continue, Europe Terminal Operators (ECT) and A.P. Moller - Maersk are building a new container complex that will expand capacity at Rotterdam by an additional two million TEU containers a year. 因人们预计集装箱的运输量将持续增长,欧洲港口运营公司(ECT)和A.P.穆勒—马士基公司正在联合新建一条集装箱码头,这样鹿特丹港每年将可以吞吐多2百万个TEU的集装箱。

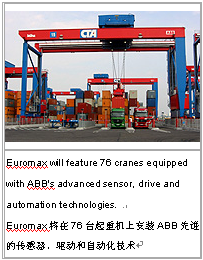

Euromax will feature 76 cranes equipped with ABBs advanced sensor, drive and automation technologies. Euromax将在76台起重机上安装ABB先进的传感器、驱动和自动化技术 The new Euromax Terminal will make Rotterdam larger than the combined capacity of its three nearest European rivals – Antwerp, Hamburg and Marseille – and strengthen its position as one of the world’s most important container hubs. 新的Euromax港口将使鹿特丹的年吞吐量比其最近的三个竞争对手—安特卫普、汉堡和马赛的年吞吐量总和还多,并且使其成为世界上最重要的集装箱中心之一。 Euromax will feature the most modern technology available: 16 semi-automated quay cranes, 58 fully automatic rail-mounted stacking cranes, two cranes for loading and unloading rail wagons – all equipped with ABB’s advanced sensor, drive and automation technologies – and driverless vehicles for transporting containers from the quay. Euromax将运用最先进的技术:16台半自动港岸起重机,58台全自动吊轨堆放起重机,2台用于装卸的有轨车的起重机,这些起重机全部安装了ABB先进的传感器、驱动和自动化技术,而且更有无人驾驶拖车从码头运输集装箱。 The storage yard will house 40,000 TEU containers stacked up to five high by automatic stacking cranes with system features like message interface for automated order handling, container recognition for quick identification of containers, target positioning for the speedy location of containers and vehicles, load positioning for accurate container placement, and remote control for truck handling – all of which are key functions for rapid, accurate and safe operation. 堆存码头将可以容纳4万个TEU的自动堆放起重机堆存起来的集装箱。这些起重机具有如下的系统特点:自动命令处理信息界面,快速识别集装箱的集装箱识别功能,集装箱和拖车的快速目标定位功能,准确放置集装箱的负载定位功能,拖车处理的远程控制等等,这些功能均是快速、准确、安全操作的重要保障。 ABB was awarded the order by Euromax and is working in conjunction with Shanghai Zhenhua Port Machinery Company (ZPMC), the world’s largest terminal crane contractor. ABB的定单由Euromax提供,ABB将与世界上最大的港口起重机制造商上海震华(音译)港口机械公司一起完成此工程。