In order to enhance market competitiveness, an auto parts manufacturer decided to implement a strategic upgrade and introduce migration technology AI+3D vision technology to raise the production process of automotive sunroofs from automation to a new level of intelligence. The upgrade is expected to significantly expand its capacity scale and production quality, and achieve a leapfrog improvement in manufacturing technology.

In the face of growing demand for orders, the market has also put forward higher standards for production quality and efficiency.

The skylight and the material frame of the car are large, and the operation of the single person is not only difficult but also costly when handling the ultra-long workpiece.

In this project, the Epic Eye Laser L 3D industrial camera of migration technology was used to guide the Eston robot arm to place the car sunroof yard into the 6 pillars around the material frame to realize unmanned loading and unloading.

±0.5mm

High precision error-free identification

Faced with a complex environment of six pillars around the frame, the 3D vision system had to overcome recognition challenges. At the same time, the material frame used by the customer has two different models and different sizes, which further increases the difficulty of identification.

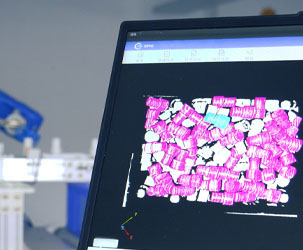

The 3D vision system can accurately identify and position the material frame, calculate the key characteristics of the discharge box, including the position of the column, model number, etc., and determine their coordinate values and deflection angles. Through accurate comprehensive calculations, the system can output the exact placement position of each car sunroof. This high-precision recognition capability ensures that the car sunroof can be accurately access the basket, and the recognition accuracy is controlled within ±0.5mm.

Embedded intelligent algorithms

Real-time optimization of motion trajectories

Transfer Technology's 3D industrial cameras incorporate advanced deep learning algorithms and high-precision template matching technology to stably identify and accurately grasp tightly fitting car sunroofs. This system can not only quickly adapt to the introduction of new products in the field of automobile sunroof, meet the needs of production line expansion, but also intelligently plan the grasping path, and effectively deal with complex situations such as workpiece stacking and dislocation.

Strong anti-jamming

No fear of skylight glass and ambient light reflection

The lighting design of the plant uses large areas of floor-to-ceiling Windows to allow for natural light. However, this design brings in too much light and puts higher demands on the 3D camera's ability to resist ambient light interference. In addition, the glass material of the car sunroof will also cause certain interference to 3D visual recognition.

Transfer Technology's Epic Eye Laser L system demonstrates excellent resistance to ambient light interference, up to 120,000 lux, by using a laser as a projected light source combined with binocular structured light imaging technology. The system ensures that the generated point cloud data is complete and available even in a window or shop floor environment where it is difficult to block light.

In addition, the Epic Eye Laser L system is equipped with a self-developed exposure imaging control algorithm. This algorithm can obtain complete and clear high-quality point cloud data for transparent and black reflective objects, further improving the accuracy and reliability of 3D visual recognition.

Time:2024-09-07

Time:2024-09-07 Return to List

Return to List