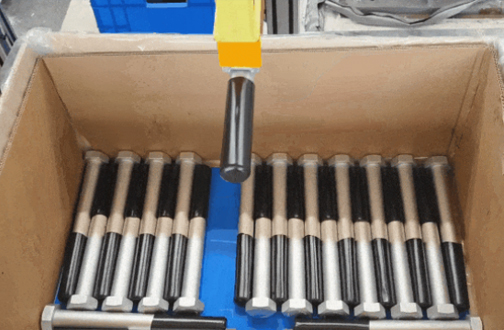

There are many drawbacks in the traditional manual loading and unloading of aluminum ingots, such as low efficiency, high labor intensity, poor working environment, and high error rate and safety hazards caused by human factors, which limit the improvement of production efficiency and the guarantee of operation quality, but also increase the operating costs of enterprises and the health risks of employees.

Therefore, the customer wanted to provide an efficient, accurate, flexible and cost-effective solution for aluminum ingot grasping by introducing the intelligent combination of 3D vision + robotic arm.

Aluminum ingot appearance consistency is poor, reflection is more serious;

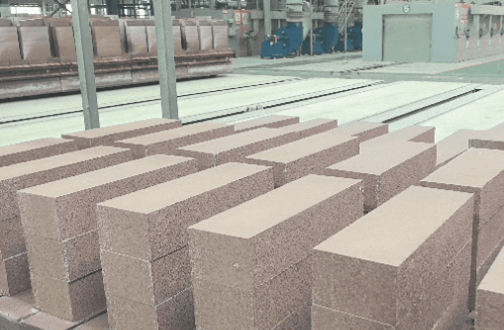

Aluminum ingots are stacked cross-over, and the size of the stack is large.

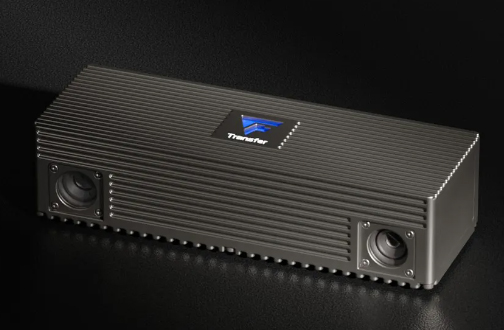

In this project, the Epic Eye Laser L laser camera, Epic Pro software and KUKA robot arm were selected to work together to realize the automatic handling of aluminum ingots.

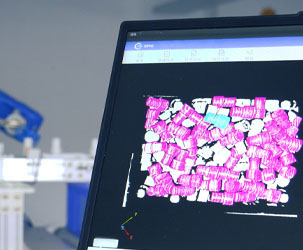

The Epic Eye Laser L, with its wide field of view and accurate measurement capabilities, acts as the "eye" of the solution, responsible for capturing the precise position and pose information of the aluminum ingot. Epic Pro software is the "brain" of the solution, responsible for intelligent identification and path planning; The KUKA robotic arm acts as the "arm" of the solution, performing precise grasping actions to safely place the ingots in the desired position.

±2mm recognition accuracy

Not afraid of high reflective influence

In the automated loading and unloading process of aluminum ingots, the laser camera demonstrated an excellent ability to cope with highly reflective characteristics, which brought significant value to the customer.

The Epic Eye Laser L camera can maintain high quality imaging even under the interference of bright light exceeding 120,000 Lux. This advantage can ignore the highly reflective characteristics of the aluminum ingot and accurately capture its three-dimensional information. It not only improves grasp accuracy and operational efficiency, but also reduces identification errors caused by reflections, thereby reducing material waste and production disruptions, bringing greater production stability and cost effectiveness to customers.

Blessed by intelligent algorithms

Don't be afraid to cross stack

When handling aluminum ingots with large stack size and cross-stacking, the 3D vision system is equipped with advanced AI algorithm and deep learning technology, which can intelligently identify the stacked aluminum ingots and accurately estimate the pose of the stack shape.

This not only improves the success rate of identification, but also ensures stability and safety when handling large size stacks. The intelligent trajectory planning algorithm can calculate the optimal grasping path, avoid collision, improve operation stability, and work reliably even in the environment of compact space and serious interference.

Time:2024-10-21

Time:2024-10-21 Return to List

Return to List