In today's wave of industrial automation, 3D vision technology is becoming the key to improving production efficiency and safety. Especially in the refractory industry, such as the production of magnesia-calcium bricks, the application of automatic loading and unloading system is particularly important.

This article will introduce brieflyHow can 3D visual guidance technology optimize the automated loading and unloading process of magnesia-calcium bricksTo explore its positive impact on improving production efficiency, reducing costs and enhancing operational flexibility. Through practical application cases, the important role and potential value of 3D vision technology in modern industrial production are further explained.

The challenges of traditional manual loading and unloading of magnesia-calcium bricks includeHigh labor intensity, low production efficiency, safety risk and quality control difficulty. Manual operation is difficult to ensure the accuracy and consistency of loading and unloading, which is easy to lead to low production efficiency and product quality fluctuations. At the same time, manual handling is difficult to adapt to the expansion of production scale and the needs of product diversification.

solution

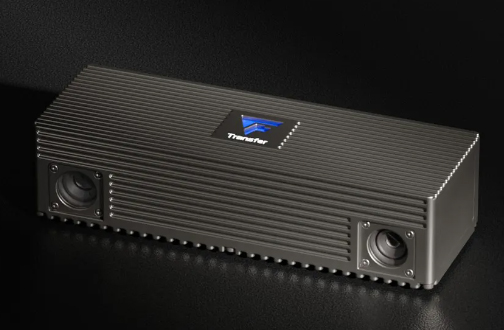

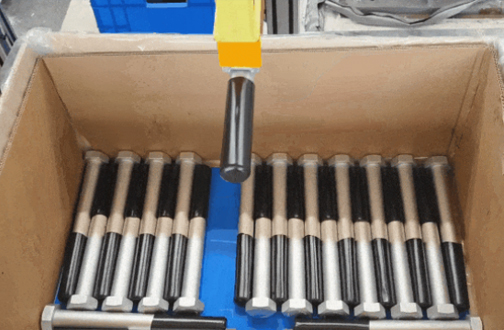

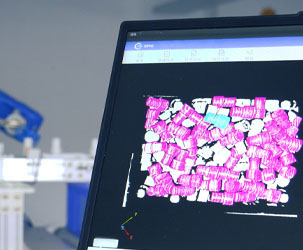

In order to effectively address the above challenges, enterprises have adopted an automated loading and unloading strategy that integrates AI and 3D vision technology. The policy is deployedEpic Eye Laser L Series industrial 3D cameras with Epic Pro softwareCutting-edge 3D visual recognition and deep learning technology is used to accurately locate and stably grasp magnesia-calcium bricks, thereby automating the production process.

systematicThe recognition accuracy reaches ±2mmWith the robot's grasping accuracy of ±5mm, it ensures the high accuracy of the loading and unloading process, reduces the error and scrap rate in production, and directly improves the quality and consistency of the product.

Ultra-fast response

Taking pictures takes about 2.8 seconds, and the algorithm processing time is about 3 seconds, which means that the system can complete the identification and positioning of the workpiece in a short time, speeding up the production rhythm and improving the overall production efficiency.

Strong environmental adaptability

The 3D vision system has excellentResistance to ambient light interferencePerformance, and can operate stably in changeable industrial environments, including dust, vibration, humidity, high temperature and other harsh conditions, to ensure the continuity and stability of production.

With the continuous progress and application of 3D visual guidance technology, automated loading and unloading systems are becoming a key factor in manufacturing to improve production efficiency and product quality. The technology not onlyProduction processes are optimized, labor costs are reduced, and operational flexibility and accuracy are enhancedIt has brought significant economic benefits and competitive advantages for enterprises.

Looking to the future, with the further maturity of technology and the expansion of application fields, 3D vision guidance technology will continue to lead the innovation trend of industrial automation and contribute to the intelligent transformation of the manufacturing industry.

Time:2024-10-21

Time:2024-10-21 Return to List

Return to List