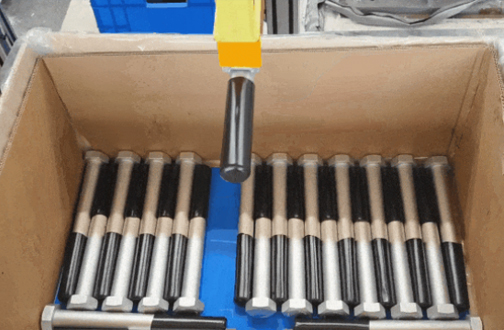

According to the World Steel Association, in 2022, China’s crude steel production reached 1.05 billion tons, accounting for 56.5% of the global total. During the 13th Five-Year Plan period, an average of 300 million tons of steel was used for welding processing annually, making up over 50% of the global processing volume. China’s welding production continues to lead globally.

The launch of Transfer Technology's Epic Eye Pixel Welding will empower our partners create innovative “welding integration” solutions, enabling flexible application in a variety of welding scenarios.

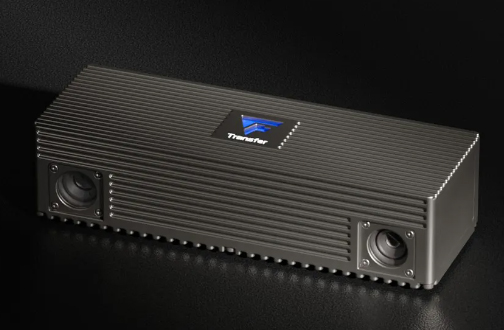

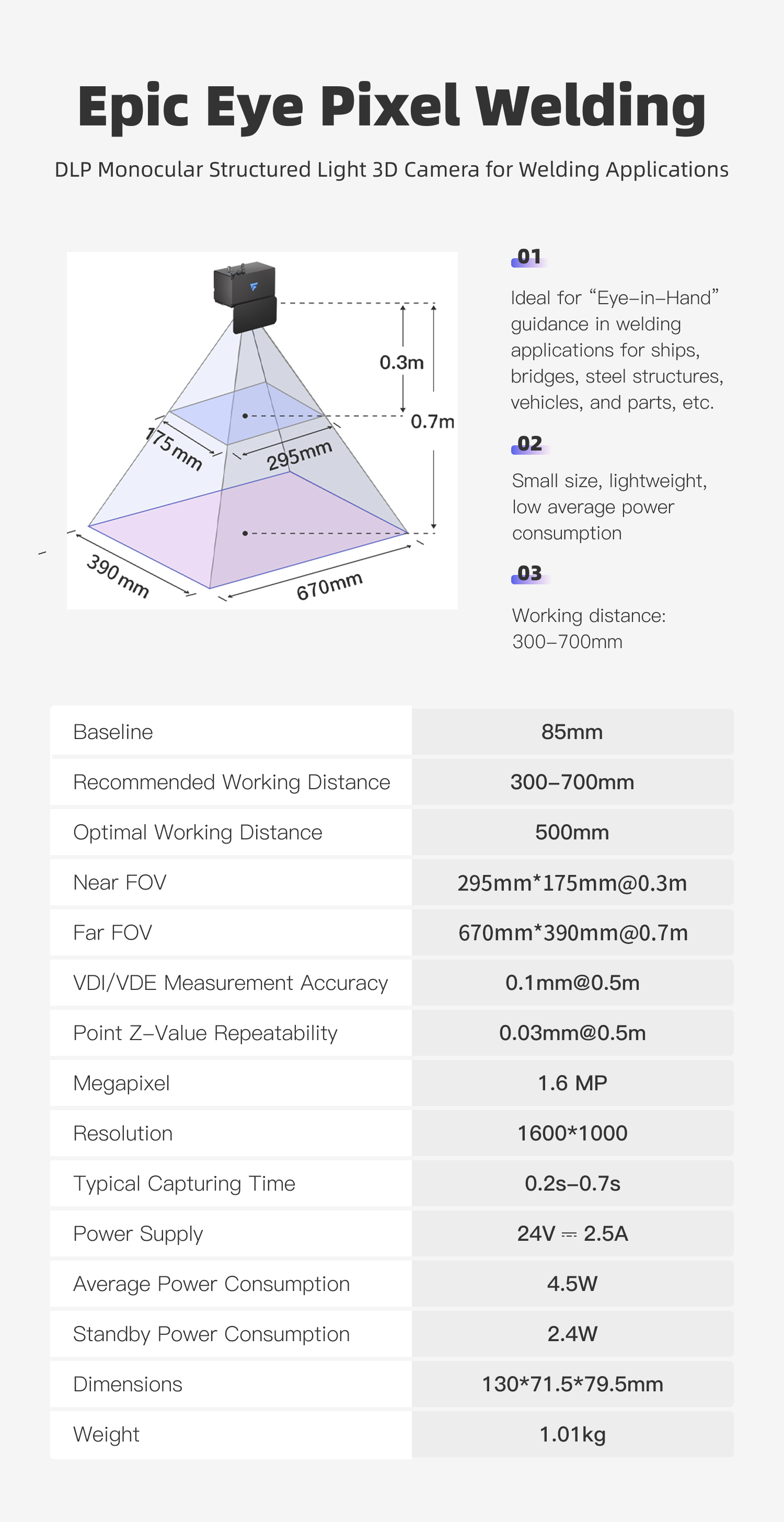

Transfer Technology's Epic Eye Pixel Welding 3D Camera adopts independently developed structured light technology, equipped with powerful imaging chips that output high-resolution point cloud data. With its compact size, light weight, low power consumption, fast imaging speed, and easy integration with robot end-effectors, this camera can be used with various types of welding robots, addressing tasks like workpiece positioning and recognition, multi-robot collaborative welding, and weld seam recognition. It’s ideal for industries like shipbuilding, bridges, steel structures, and automotive parts, helping users enhance production efficiency.

Carrying Forward All the Advantages of the Pixel Series Cameras

Lightweight, compact, low power consumption, and fast Capture speed

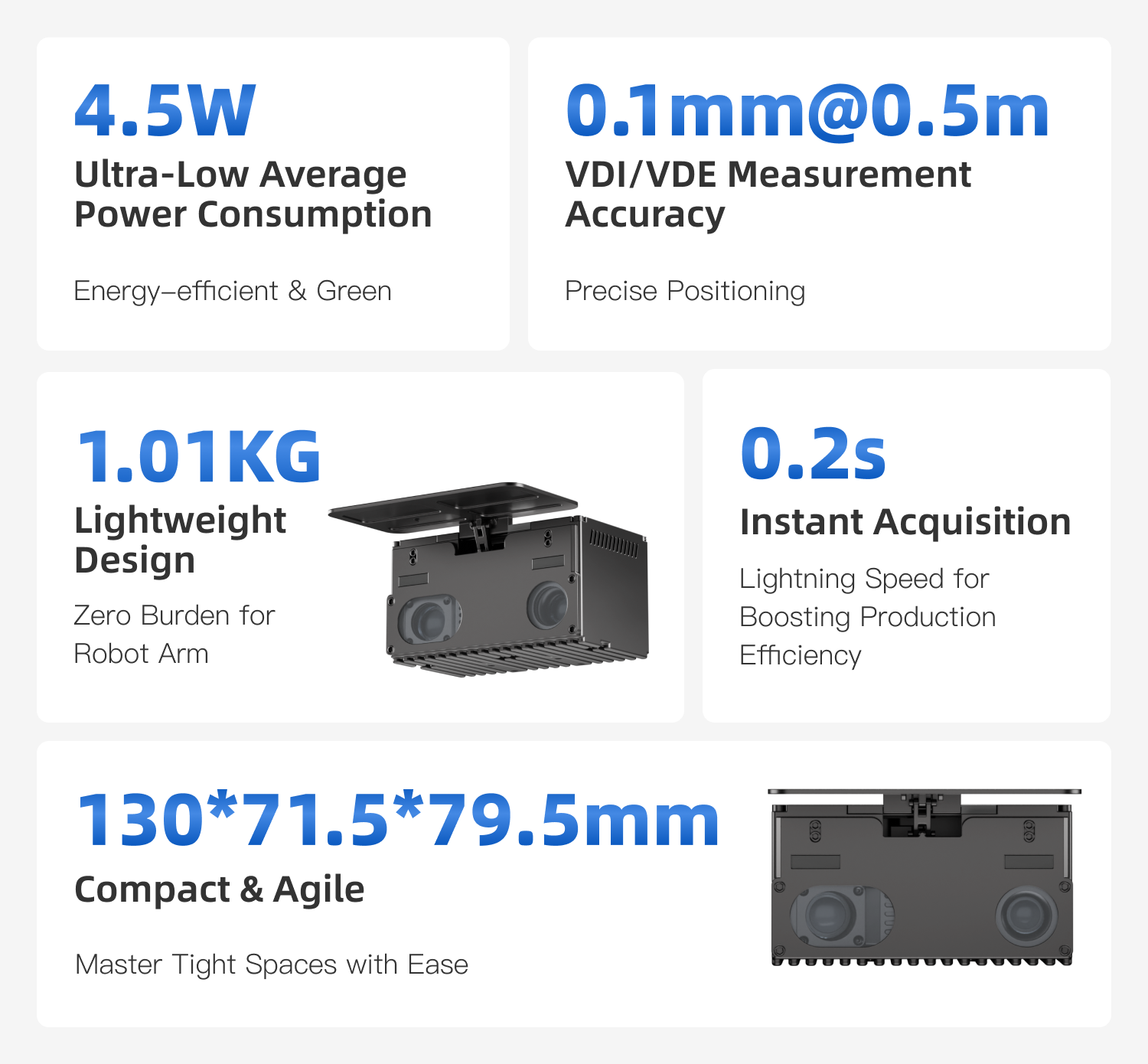

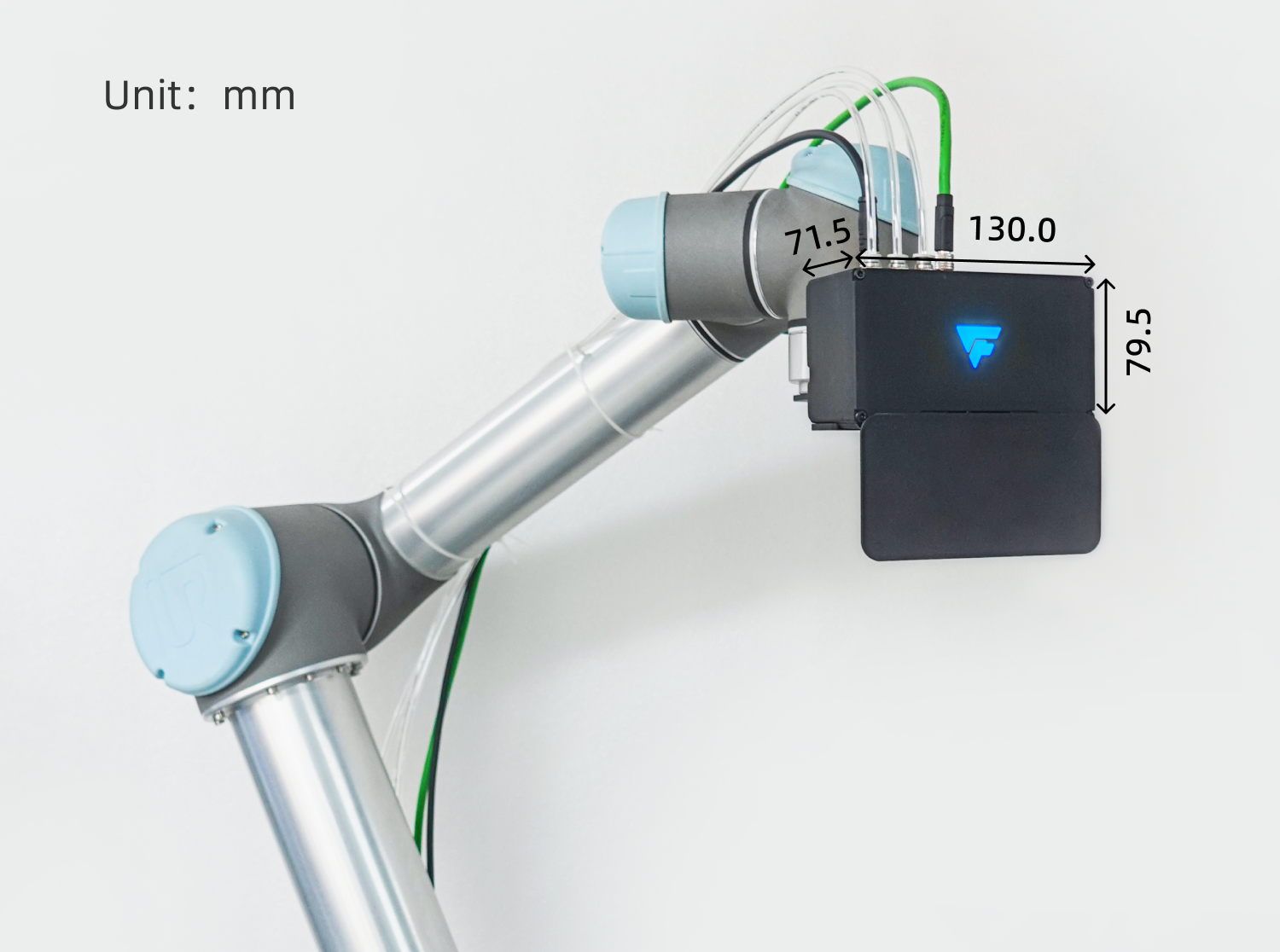

The Epic Eye Pixel Welding camera continues all the advantages of the Pixel series: lightweight, compact, low power consumption, and fast image capture. To meet the demands of welding applications, it also features a protective cover for enhanced lens protection, ensuring stability, reliability, and continuous performance during operations.

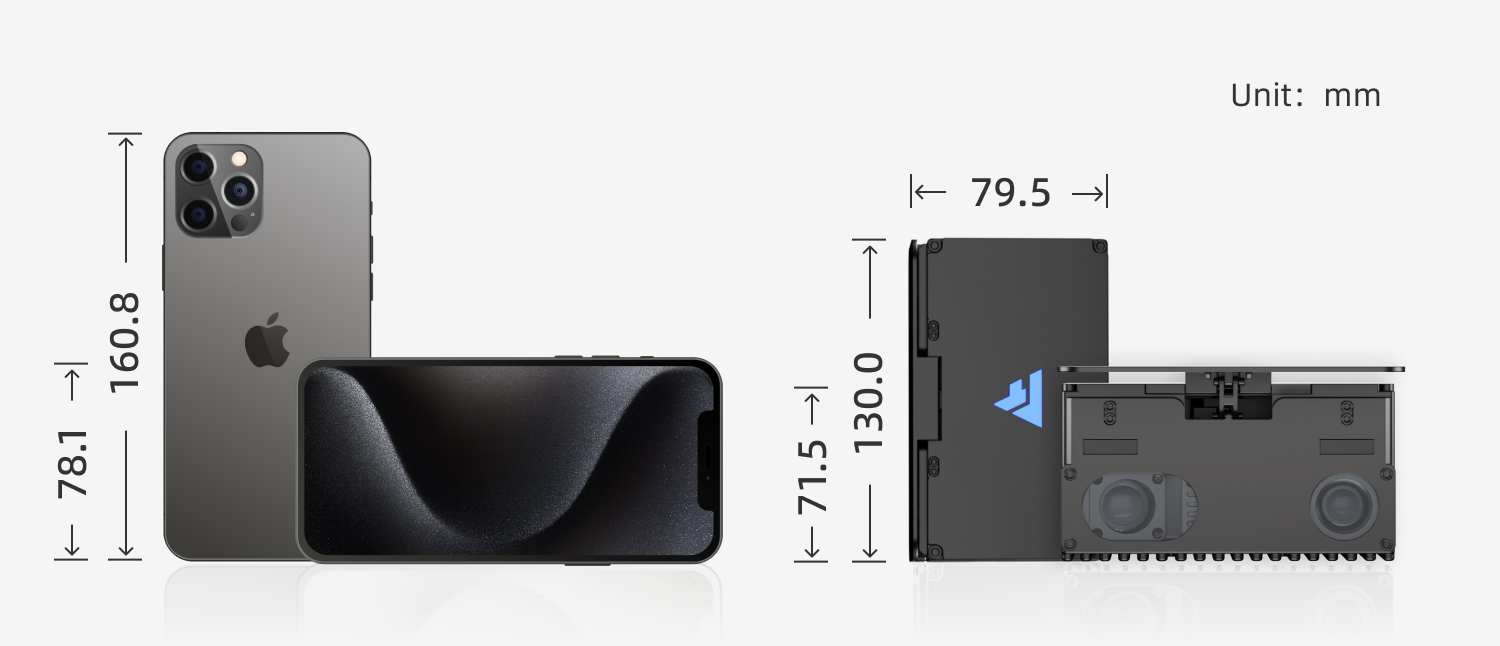

Thanks to the overall design advantages of the Pixel series, this product stands out in terms of size and weight compared to other products with similar benchmarks: the camera (including protective cover) weighs only 1.01kg, with dimensions of 130mm x 71.5mm x 79.5mm—30.8mm shorter and 6.6mm narrower than an iPhone 16 Pro Max. This makes it highly friendly for robot end-effector payloads and offers flexibility for robots working in complex or narrow environments.

With an average power consumption of 4.5W, standby power consumption of 2.4W, and a capture speed of 0.2 seconds, the Epic Eye Pixel Welding camera enables the rapid capture of point cloud images during the welding process, providing instant data for system adjustments.

This ensures both the immediacy and accuracy of welding operations, effectively speeding up production cycles. Furthermore, its ultra-low power consumption also significantly reduces operational costs over the long term, especially in welding tasks involving collaborative robots, where it minimizes power loss caused by equipment operation.

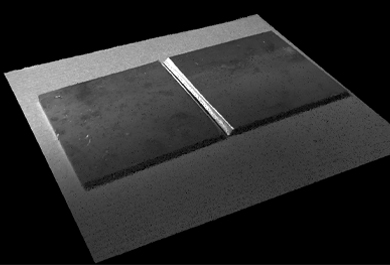

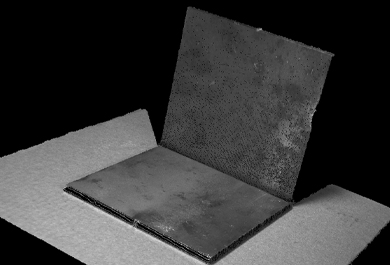

High-Precision, High-Quality Point Cloud Imaging

Sub-millimeter imaging, ideal for most welding scenarios

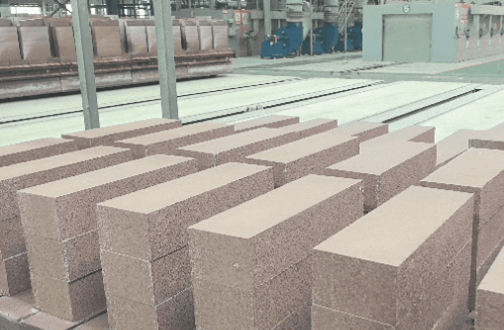

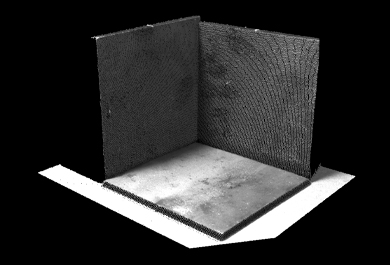

To ensure precision and accuracy in welding tasks, the Epic Eye Pixel Welding uses blue stripe structured light, achieving a precision of ±0.1mm within the range of 0.5m–0.7m. This technology effectively capturing complex workpieces with characteristics like edge reflection, rust, dull surfaces, and slag, capturing complete and accurate point cloud data. This precise data is crucial for weld seam positioning and welding path planning, ensuring high-quality welding execution.

Compared to other imaging technologies, structured light uses a high-brightness DLP projector to project grids and analyze deformations to obtain 3D data. This technique can generate high-quality, sub-millimeter precision point cloud data for objects with various materials and reflective characteristics, providing advantages like fast scanning, clear imaging, and accurate positioning. In addition, it can capture 3D data over a larger area, making it ideal for welding large workpieces and enhancing welding efficiency.

Committed to Collaborative Ecosystem, Ensuring Easy "Integration"

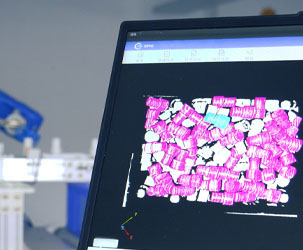

SDK Interface Supporting Custom Development for Versatile Applications

Considering the need for "vision secondary development," the Epic Eye Pixel Welding offers mature SDK interface, supporting integration with third-party vision software such as Halcon, allowing flexible applications and further development by partners and developers.

Built for Extreme Environments

IP65 Protection, Reliable Operation from -20°C to 70°C

In the design of the Epic Eye Pixel Welding camera, special considerations were made to withstand the harsh conditions of welding environments. It is equipped with specialized protective lenses and active cooling components to handle high temperatures, dust, spattered slag, humidity, oil contamination, and other challenges, effectively prolonging its lifespan and reducing maintenance costs.

With an IP65 protection rating, the Epic Eye Pixel Welding camera ensures safe and stable operation in temperature environments ranging from -20°C to 70°C.

Time:2025-02-08

Time:2025-02-08 Return to List

Return to List